ALL ABOUT LETTERPRESS

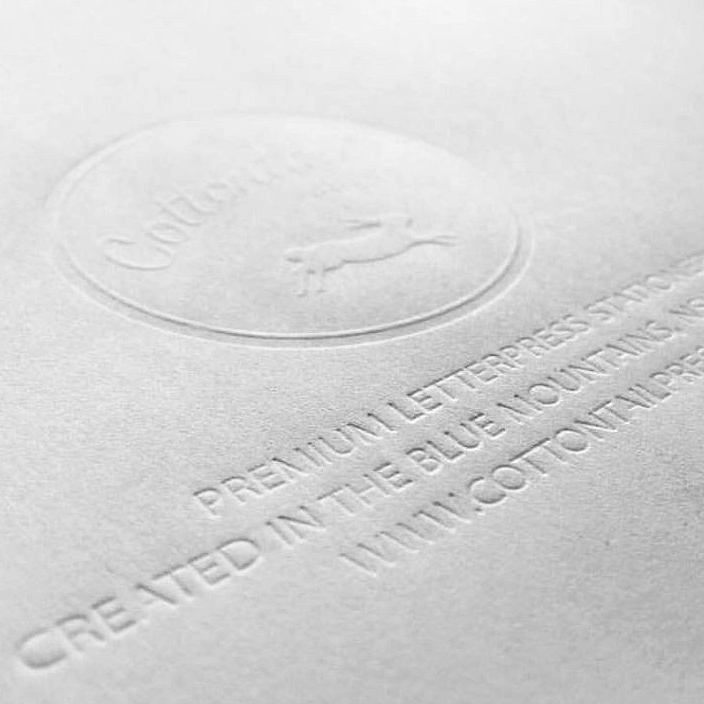

Letterpress is a form of relief printing using a printing press in which a printing surface (a plate) is inked and then is pressed against paper to create a print. Relief printing is where the positive parts of the image are raised on the printing plate above the negative, or non-printing areas. It is this technique that allows the creation of an impression (or debossing) of the print into the paper. Our soft 100% cotton papers allow a deep impression that is visually stunning and luxuriously tactile.

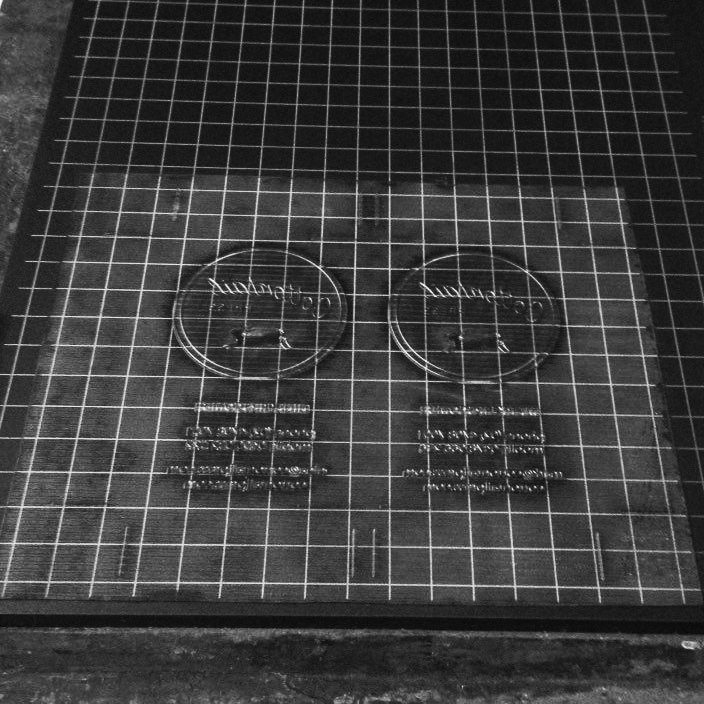

Commercial letterpress has been largely abandoned in favour of faster and lower cost technologies such as offset and digital printing. However, today letterpress is enjoying a revival as the ideal process for creating stunning bespoke pieces such as wedding invitations, art prints and business stationary. The making of letterpress prints is a slow and precise process that begins with creating unique printing plates for each colour of the design, followed by the hand-mixing of inks and then each print is ‘pulled’ individually by our expert printmakers.

ALL ABOUT LETTERPRESS

Letterpress is a form of relief printing using a printing press in which a printing surface (a plate) is inked and then is pressed against paper to create a print. Relief printing is where the positive parts of the image are raised on the printing plate above the negative, or non-printing areas. It is this technique that allows the creation of an impression (or debossing) of the print into the paper. Our soft 100% cotton papers allow a deep impression that is visually stunning and luxuriously tactile.

Commercial letterpress has been largely abandoned in favour of faster and lower cost technologies such as offset and digital printing. However, today letterpress is enjoying a revival as the ideal process for creating stunning bespoke pieces such as wedding invitations, art prints and business stationary. The making of letterpress prints is a slow and precise process that begins with creating unique printing plates for each colour of the design, followed by the hand-mixing of inks and then each print is ‘pulled’ individually by our expert printmakers.

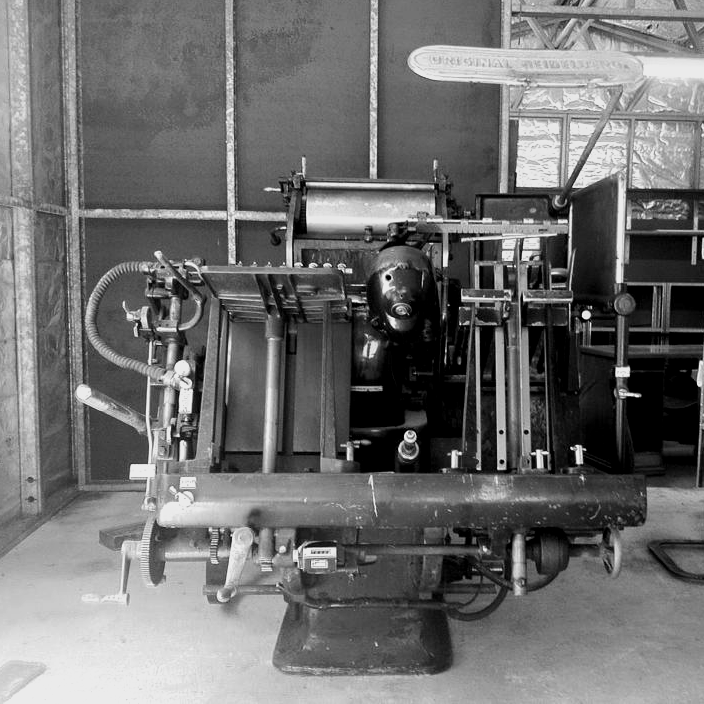

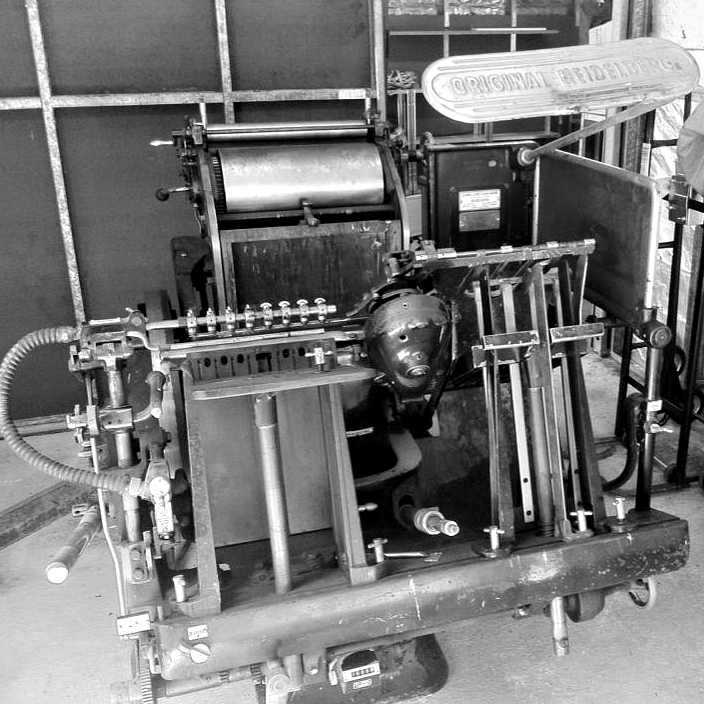

MEET WYNSTON

Wynston is our gorgeous, 2 tonne, 1953 Original Heidelberg Windmill Platen Press. Don’t let his age fool you. Even though he would be considered an antique today, he continues to prove his worth day in and day out.

How did we aquire such a unique and beautiful machine? A quick search on Gumtree (a site much like Ebay or Craigslist) led us to a man in Adelaide who happened to be selling one. He said he bought it at an auction and had plans of restoring and running the machine but never got around to it. Mark and his brother set out with a flatbed trailer to pick up this hunk of cast iron and let me tell you, this was no easy task. A 1,250 km drive later and one flat tire on the trailer, they finally made it back to the Blue Mountains. With the help of a machinest friend of ours, we carefully unloaded Wynston and rolled him into our studio.

A little more about Heidelberg Platen Presses: The Original Heidelberg press, also known as “The Prince of Presses”, was made in West Germany by Schnellpressenfabrik AG Heidelberg (Heibelberg Rapid Press Works, Inc.). This beautiful machine was masterfully crafted with its most prominent feature in mind; speed.

Work and testing began on the Original Heidelberg press in 1912. Speed, exact register and the windmill feature were added to the machine before making it’s grand debut in 1913.

Heidelberg built around 250,000 of the these platen press machines over a 30-odd year span, ending in the 70s. Unlike most mechanical machines, a Heidelberg platen press is one that is built to last. So long as they are kept well oiled and fairly clean, they’ll keep on going, making impression after impression.

MEET WYNSTON

Wynston is our gorgeous, 2 tonne, 1953 Original Heidelberg Windmill Letterpress machine. Don’t let his age fool you. Even though he would be considered an antique today, he continues to prove his worth day in and day out.

How did we aquire such a unique and beautiful, antique machine? A quick search on Gumtree (a site much like Ebay or Craigslist) led us to a man in Adelaide who happened to be selling one. He said he bought it at an auction and had plans of restoring and running the machine but never got around to it. Mark and his brother set out with a flatbed trailer to pick up this hunk of cast iron and let me tell you, this was no easy task. A 1,250 km drive later and one flat tire on the trailer, they finally made it back to the Blue Mountains. With the help of a machinest friend of ours, we carefully unloaded Wynston and rolled him into our studio.

A little more about Heidelberg Platen Presses: The Original Heidelberg press, also known as “The Prince of Presses”, was made in West Germany by Schnellpressenfabrik AG Heidelberg (Heibelberg Rapid Press Works, Inc.). This beautiful machine was masterfully crafted with its most prominent feature in mind; speed.

Work and testing began on the Original Heidelberg press in 1912. Speed, exact register and the windmill feature were added to the machine before making it’s grand debut in 1913.

Heidelberg built around 250,000 of the these platen press machines over a 30-odd year span, ending in the 70s. Unlike most mechanical machines, a Heidelberg platen press is one that is built to last. So long as they are kept well oiled and fairly clean, they’ll keep on going, making impression after impression.